Why Are Electric Vehicles So Expensive

Electric vehicles (EVs) have gained significant attention in recent years due to their potential to reduce emissions and dependence on fossil fuels. However, one common concern that often arises is why electric vehicles tend to come with a higher price tag compared to their traditional counterparts. In this article, we will explore the reasons behind the high costs of electric vehicles and shed light on the various factors that contribute to their expense.

Initial manufacturing costs play a crucial role in making electric vehicles expensive. The production of electric vehicle components involves intricate processes and specialized manufacturing techniques, which adds to the overall cost. Additionally, the expense of battery production, a vital component of electric vehicles, further contributes to their higher price.

Research and development (R&D) expenses also play a significant role in the cost of electric vehicles. Automakers make substantial investments in developing cutting-edge technologies to enhance the efficiency and performance of electric vehicles. Ongoing R&D efforts are essential for improving battery technology, charging infrastructure, and overall user experience. While these advancements are necessary, they do increase the overall cost of electric vehicles.

Furthermore, government regulations and incentives have a significant impact on the cost of electric vehicles. Governments worldwide have implemented stringent emissions and fuel economy standards, which require automakers to invest in electric vehicle technology. While these regulations are vital for reducing greenhouse gas emissions, they can lead to higher production costs. On the other hand, governments also provide various incentives to promote the adoption of electric vehicles, such as tax credits, grants, and subsidies. While these incentives aim to make EVs more affordable for consumers, they can impact the overall cost as well.

Despite the higher price tag, it is essential to consider the long-term benefits that electric vehicles offer, including lower maintenance and fuel costs. As the technology advances and economies of scale improve, we can expect the price of electric vehicles to become more competitive in the future.

Initial Manufacturing Costs

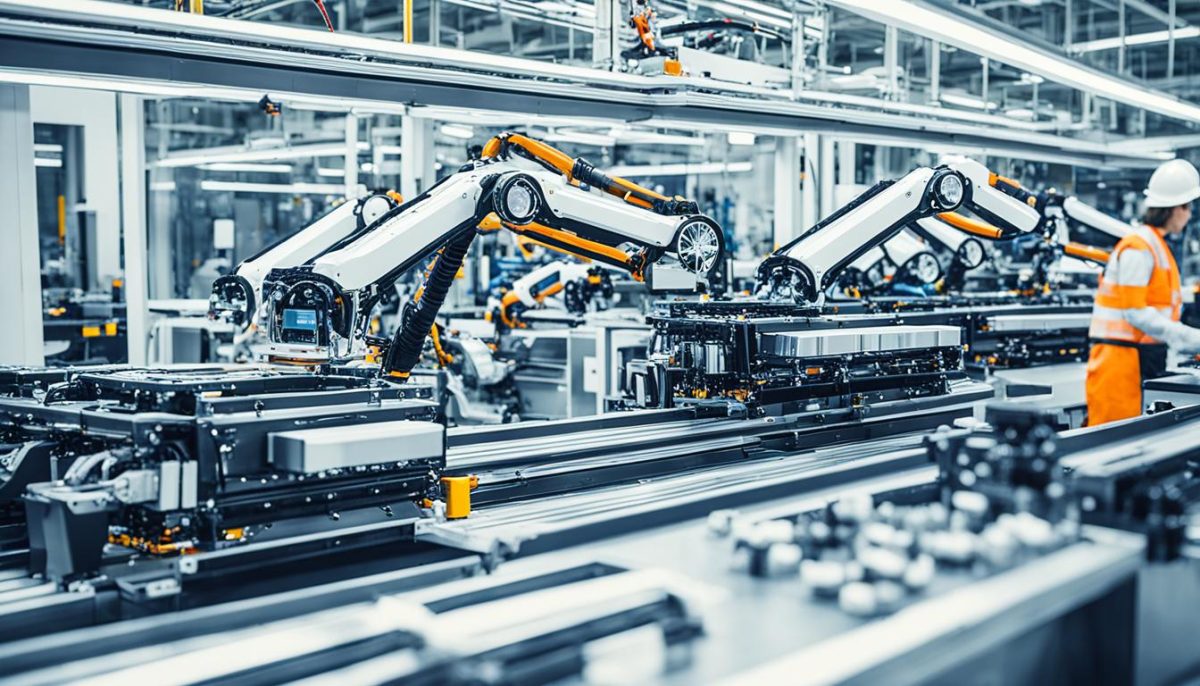

One of the primary reasons behind the high price of electric vehicles is the significant initial manufacturing costs involved. Producing electric vehicle components requires intricate processes and specialized manufacturing techniques that can be more expensive compared to traditional vehicles.

Electric vehicles rely on advanced technology and cutting-edge components such as high-capacity batteries and electric motors. These components are often more complex to manufacture and require specialized facilities and equipment, leading to higher production expenses.

Battery production, in particular, contributes significantly to the manufacturing costs of electric vehicles. The battery is the most expensive component of an electric vehicle, and its production involves the use of rare earth metals and other costly materials. Additionally, the manufacturing process for batteries requires strict quality control measures and specialized facilities, further driving up the overall manufacturing costs.

Complexities in Electric Vehicle Component Production

The production of electric vehicle components, such as batteries, electric motors, and power electronics, involves intricate manufacturing processes. For example, the production of lithium-ion batteries requires controlled environments, precise chemical mixtures, and multiple quality checks to ensure durability and performance.

In contrast, the production of traditional internal combustion engine components is more established and cost-effective due to decades of refinement and mass production. This disparity in manufacturing complexity contributes to the higher initial costs of electric vehicles.

Specialized Manufacturing Techniques

Electric vehicle manufacturing often requires specialized techniques that differ from those used in traditional automobile production. The adoption of these techniques often involves additional investments in production line retooling and training of specialized personnel.

For instance, the assembly and integration of electric vehicle battery packs require specific handling processes and precision techniques to ensure safety and optimal performance. These specialized manufacturing techniques add to the overall manufacturing costs of electric vehicles.

Research and Development Expenses

Research and development (R&D) efforts play a crucial role in the high price of electric vehicles. Automakers invest significant resources into developing cutting-edge technologies to enhance the efficiency and performance of electric vehicles. These R&D expenses are essential for pushing the boundaries of electric vehicle technology and driving innovation in the industry.

Electric vehicle manufacturers understand the importance of continuous research and improvement. They allocate substantial budgets to fund advanced research projects aimed at overcoming the limitations of electric vehicles, such as range anxiety and charging infrastructure.

One area where R&D costs are particularly significant is battery technology. The development of high-performance and long-lasting batteries is a top priority for electric vehicle manufacturers. These companies invest heavily in research to improve battery efficiency, increase energy density, and reduce production costs.

Furthermore, ongoing research is crucial for integrating cutting-edge technologies into electric vehicles. This includes advancements in autonomous driving, connectivity, and energy management systems. Automakers are constantly striving to make electric vehicles more intelligent and convenient, creating new features and functionalities that improve user experience.

R&D expenses also extend to testing and validation processes. Electric vehicle manufacturers conduct rigorous testing procedures to ensure that their vehicles meet safety standards and perform reliably under various conditions. This testing includes simulations, real-world trials, and certification processes, all of which require substantial investments.

In conclusion, the high price of electric vehicles is, in part, a result of the significant research and development expenses incurred by automakers. These investments are necessary for driving technological advancements and improving the overall performance and efficiency of electric vehicles.

Government Regulations and Incentives

Government regulations play a crucial role in shaping the cost of electric vehicles. Regulations surrounding emissions and fuel economy standards have a direct impact on the design and production of electric vehicles. Automakers are now required to invest heavily in technologies that reduce emissions and improve fuel efficiency, which adds to the overall cost of electric vehicles. Meeting these stringent regulations often necessitates the development of advanced battery systems and lightweight materials, further driving up manufacturing expenses. However, these regulations are essential for reducing pollution and promoting sustainable transportation.

On the other hand, governments worldwide are also offering various incentives to encourage the adoption of electric vehicles. These incentives aim to make electric vehicles more affordable and accessible to a wider audience. Incentives may include financial rebates, tax credits, subsidized charging infrastructure, and exemption from certain taxes or fees. By offsetting a portion of the upfront costs and ongoing expenses, these incentives help to decrease the overall cost of owning an electric vehicle. They also serve as a powerful incentive for individuals and businesses to transition to electric vehicles and contribute to a cleaner, greener future.

The combination of government regulations and incentives is crucial in driving the market for electric vehicles. While regulations may initially add to the cost, they push automakers to innovate and develop more efficient electric vehicle technologies. At the same time, incentives help to make electric vehicles more affordable, accelerating their adoption and driving economies of scale. As governments continue to prioritize sustainability and strive to reduce carbon emissions, we can expect further advancements in government regulations and incentives, making electric vehicles an increasingly viable and economical choice for consumers worldwide.